advantages:

Core team experience

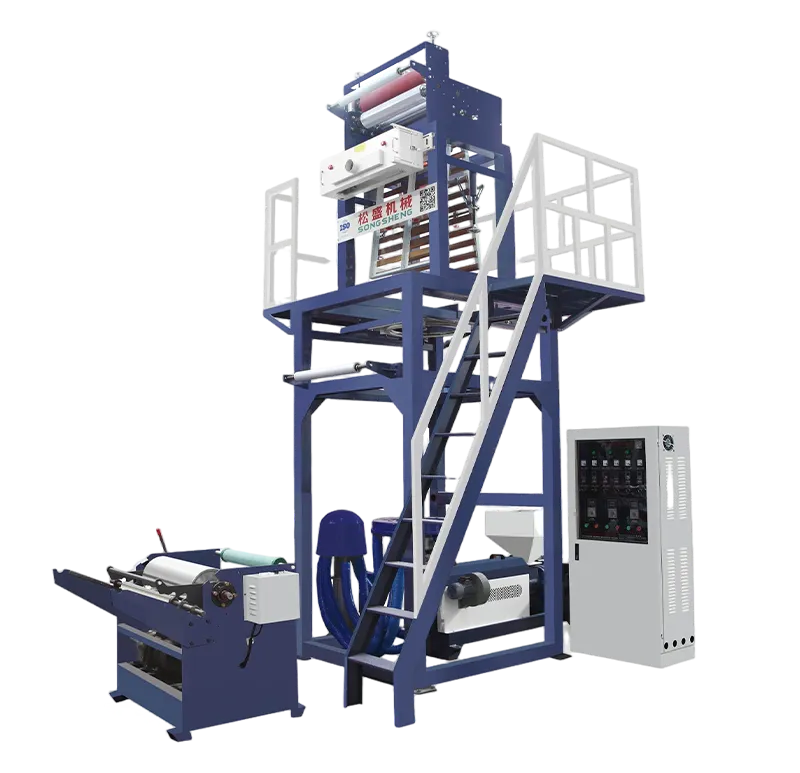

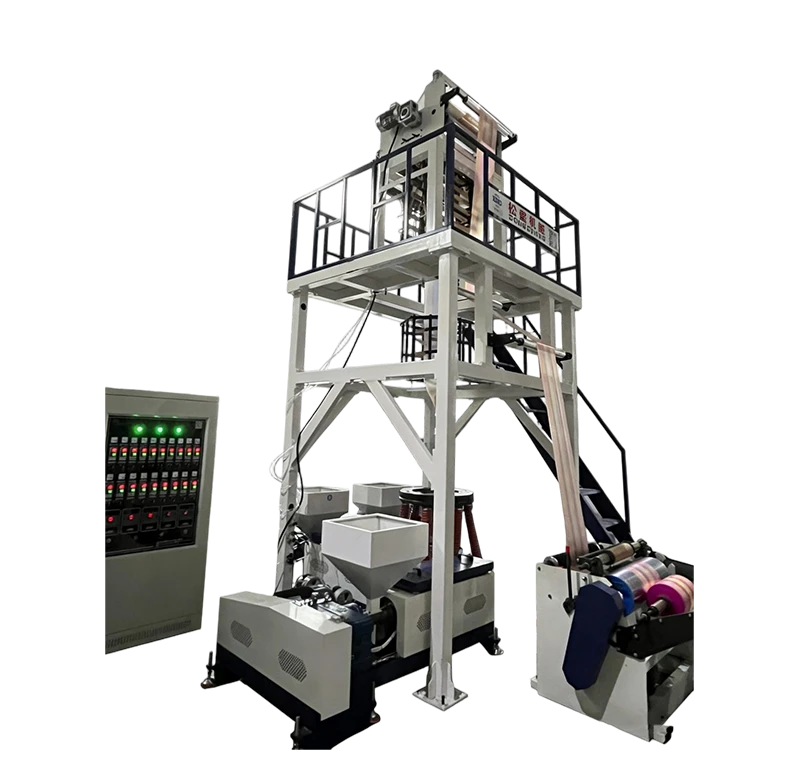

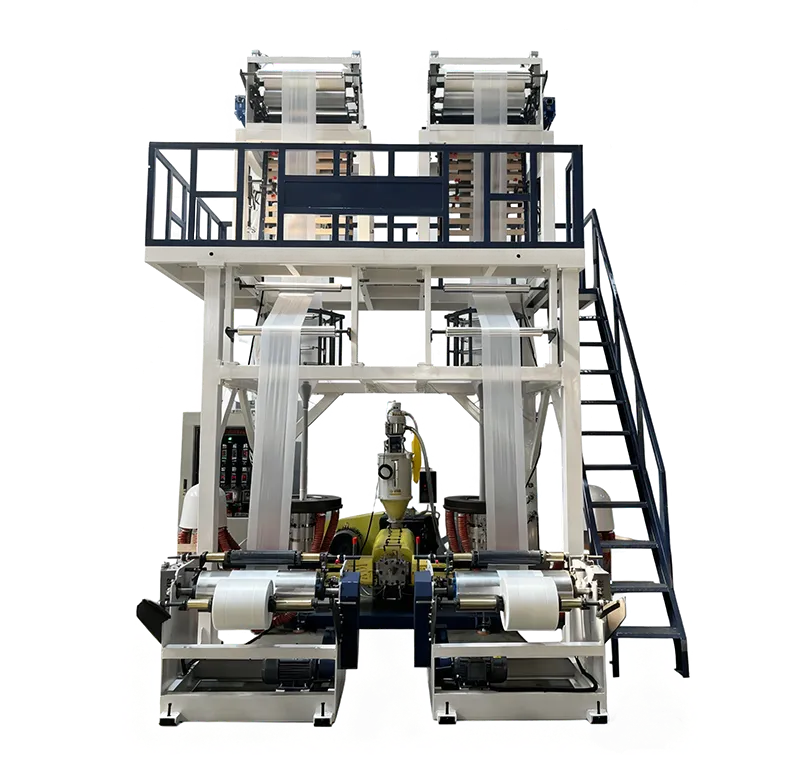

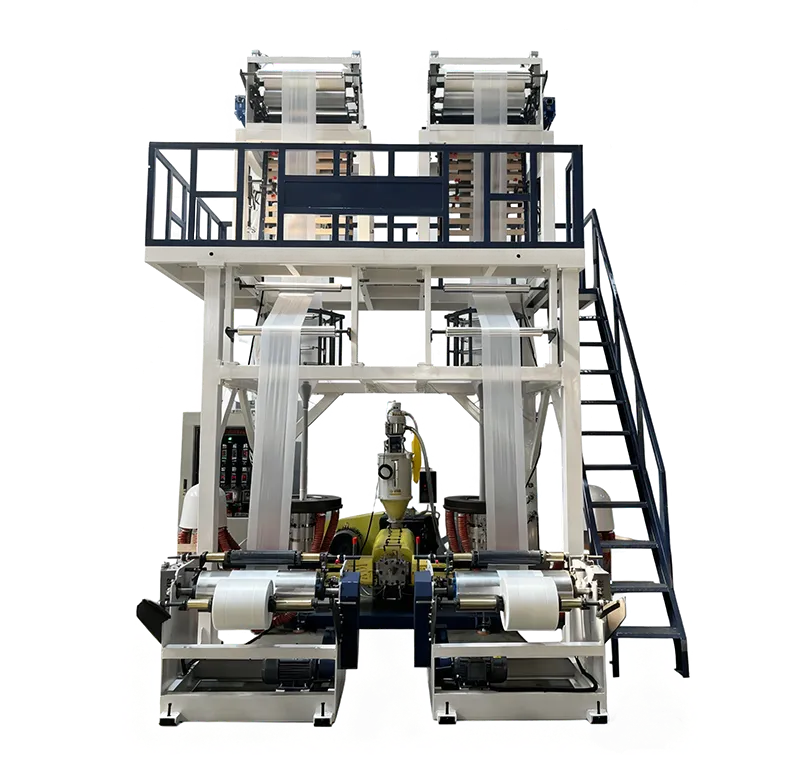

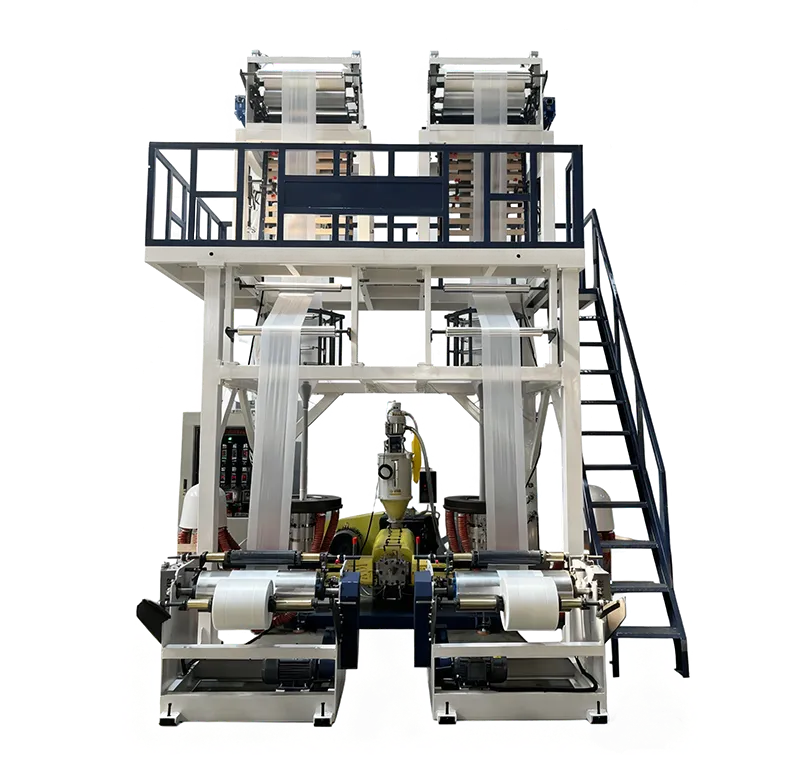

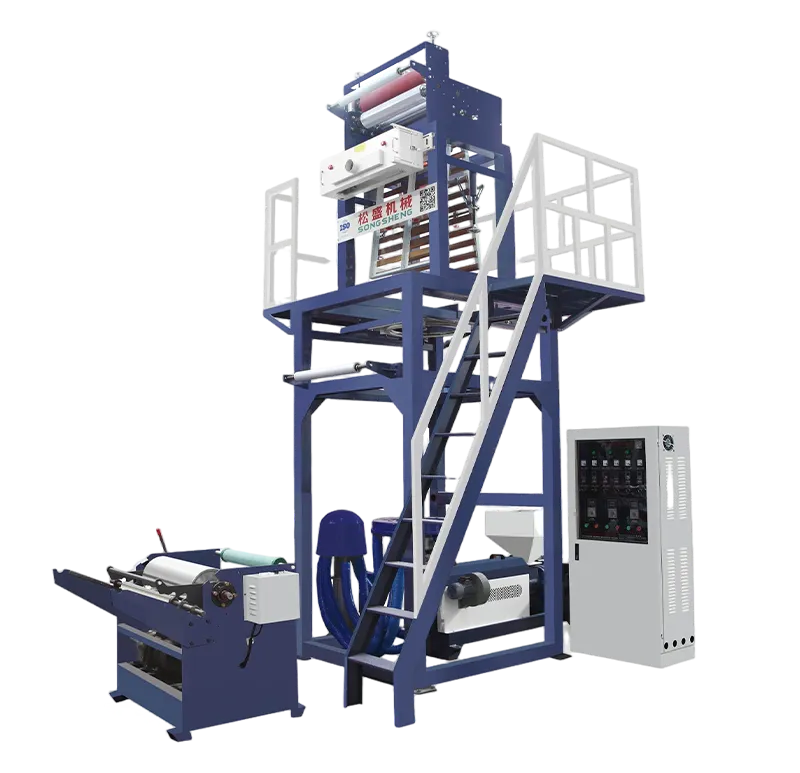

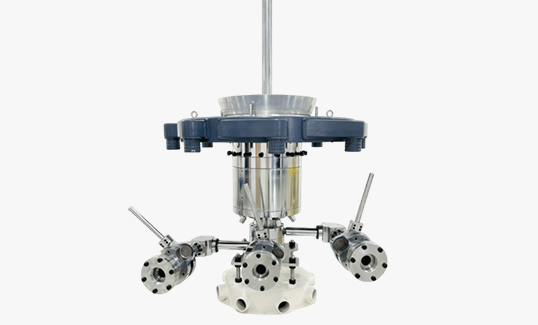

Equipment verification of the rationality of machine structure design

Serving the global market

Core Process

Extrusion efficiency

Cooling revolution

Pulling precision

Energy efficiency breakthrough

Technical Highlights

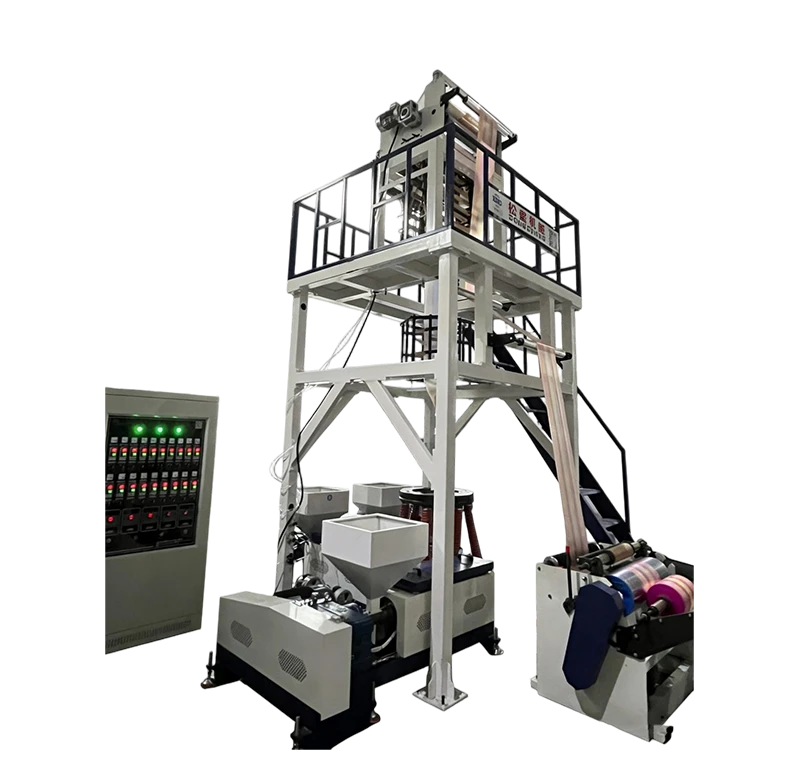

38CrMoAIA ammoniated screw

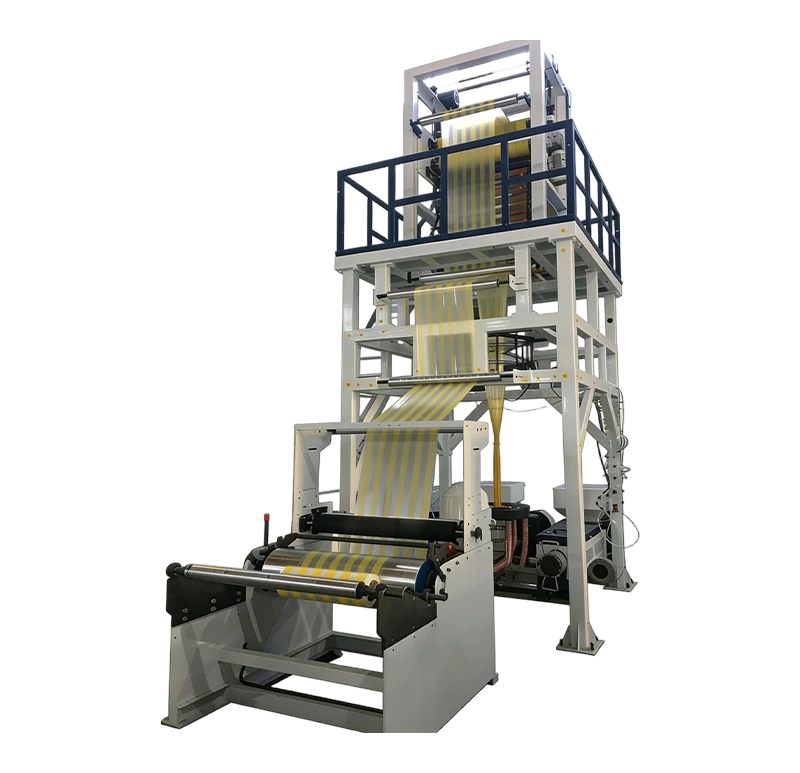

(30:1LD)IBC + Dual air ring + Pulse dust removal

(patented)+360° horizontal rotation + EPC correction

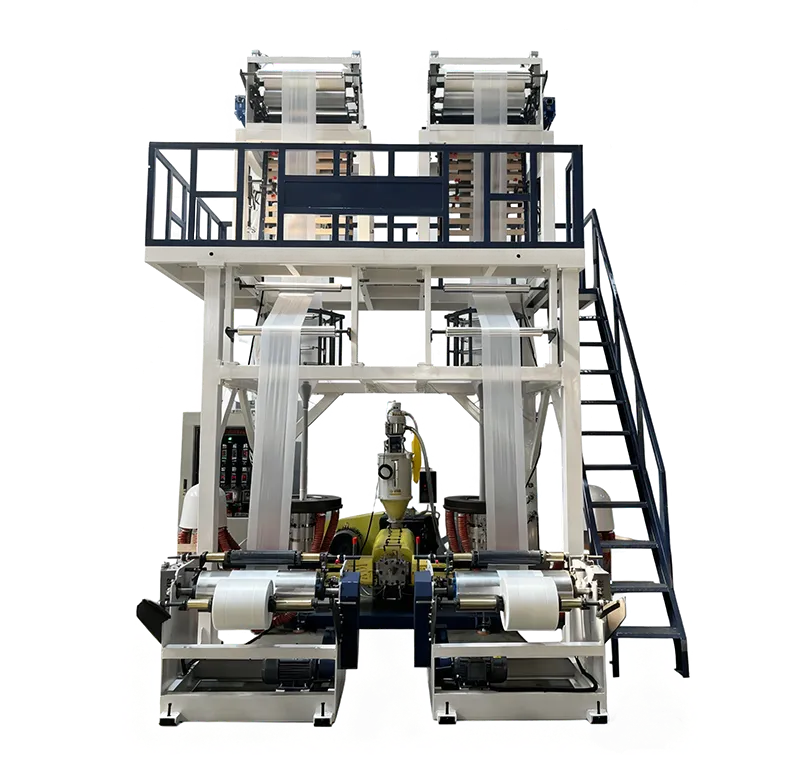

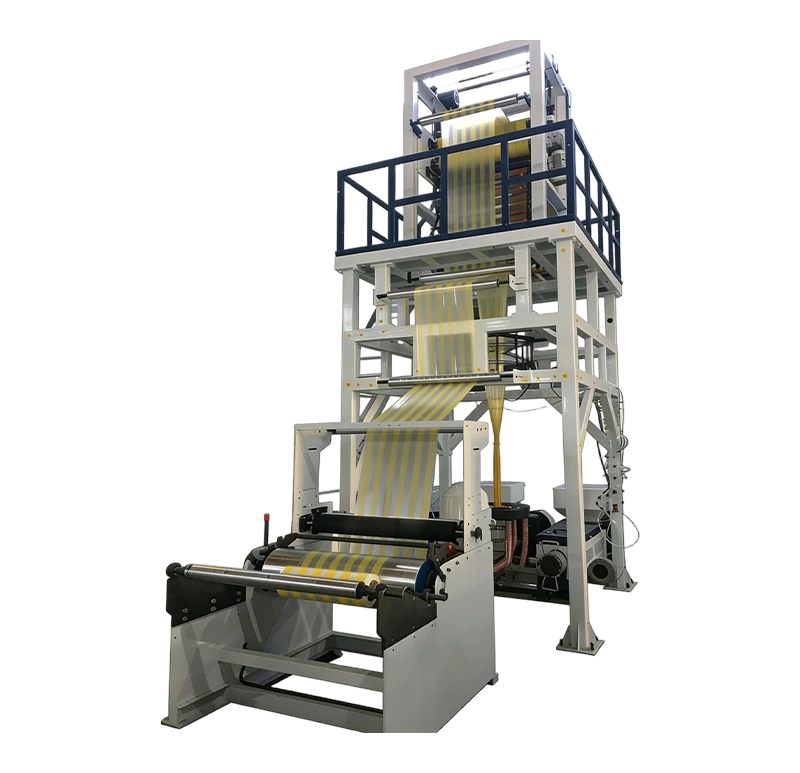

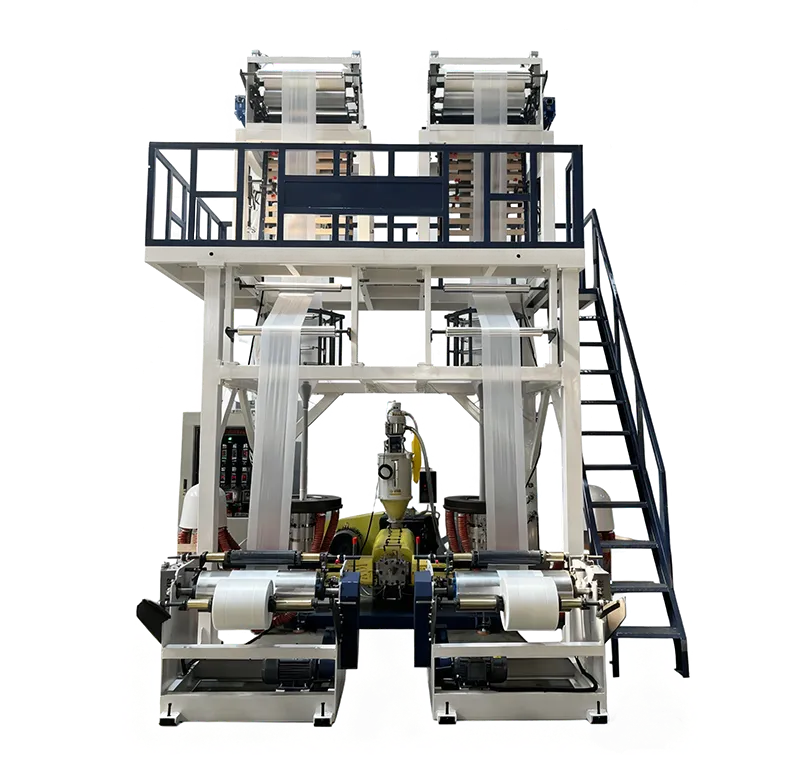

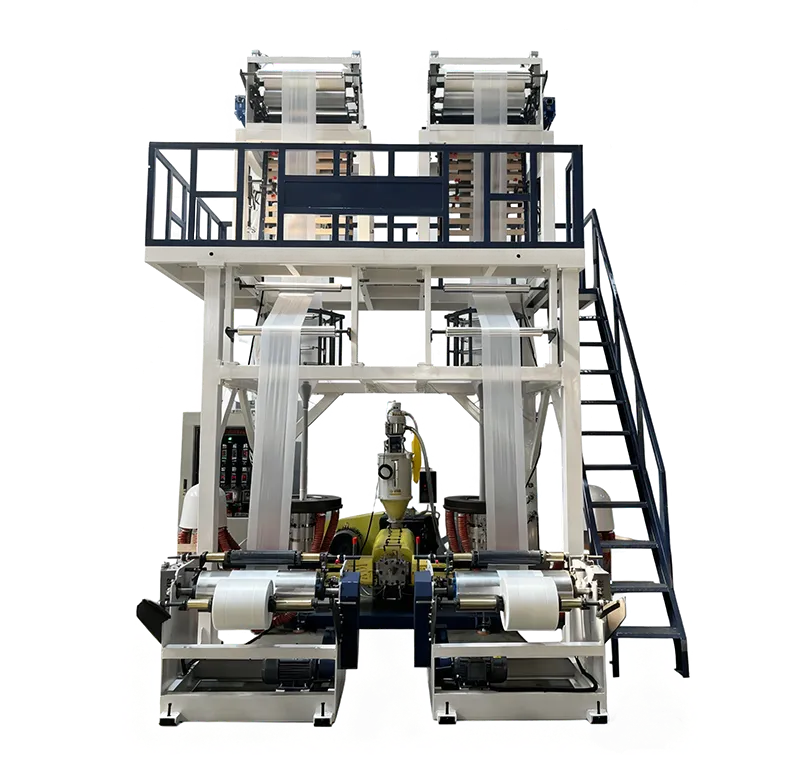

Variable frequency motor + dual die head design

Advantages

Wear life increased by↑150%

extrusion uniformity increased by↑130%

bubble stability increased by↑140%

dust defect rate decreased by↓90%

thickness error decreased to↓±3%

winding flatness improved

Energy consumption decreased by↓30%

space utilization increased by↑30%