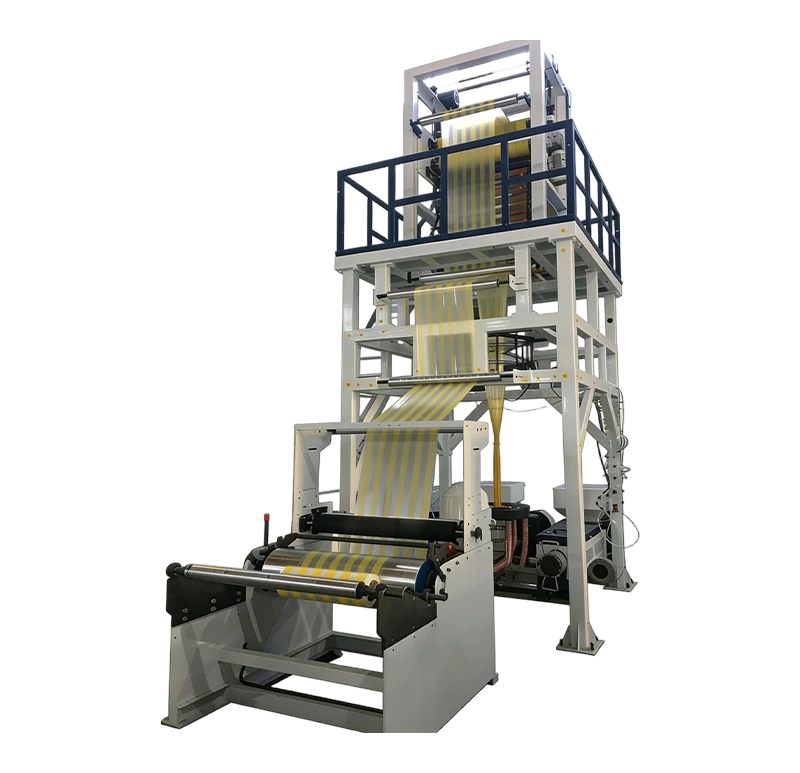

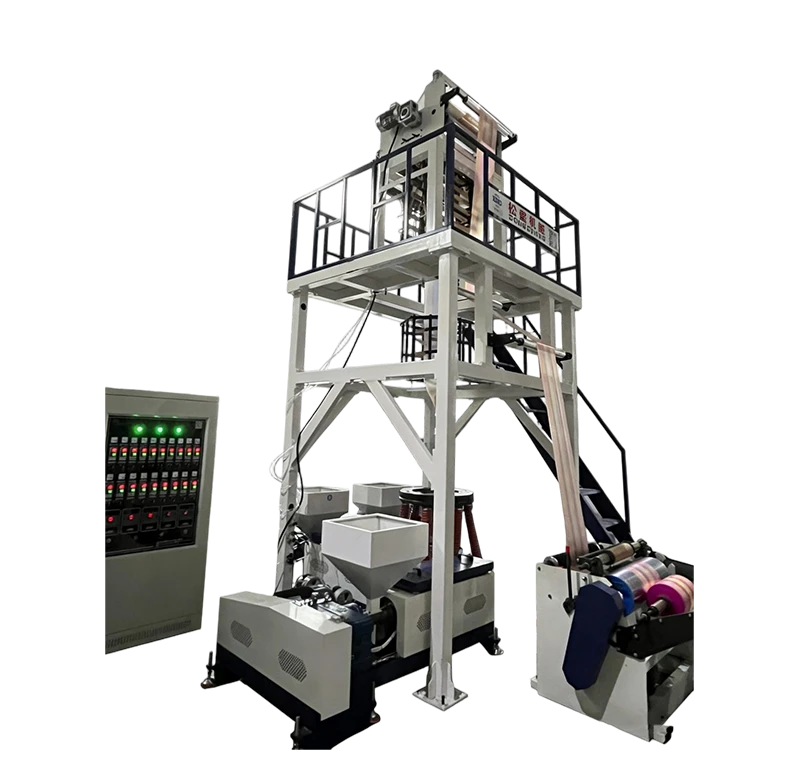

Its suitable for making high-density polyethylene (HDPE), low-density polyethylene (LDPE), and linear low-density polyethylene (LLDPE) plastic films. Color striped vest bags, garbage bags, etc. can be produced without printing, with bright colors and uniform lines, suitable for fields such as food and clothing packaging.

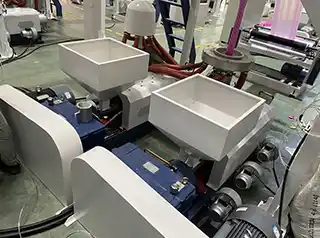

The screw and barrel are made of 38CRMOALA alloy , which has undergone nitriding treatment and precision machining, with high hardness, strong corrosion resistance, and durability;