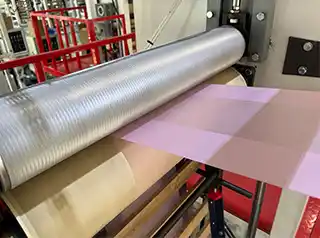

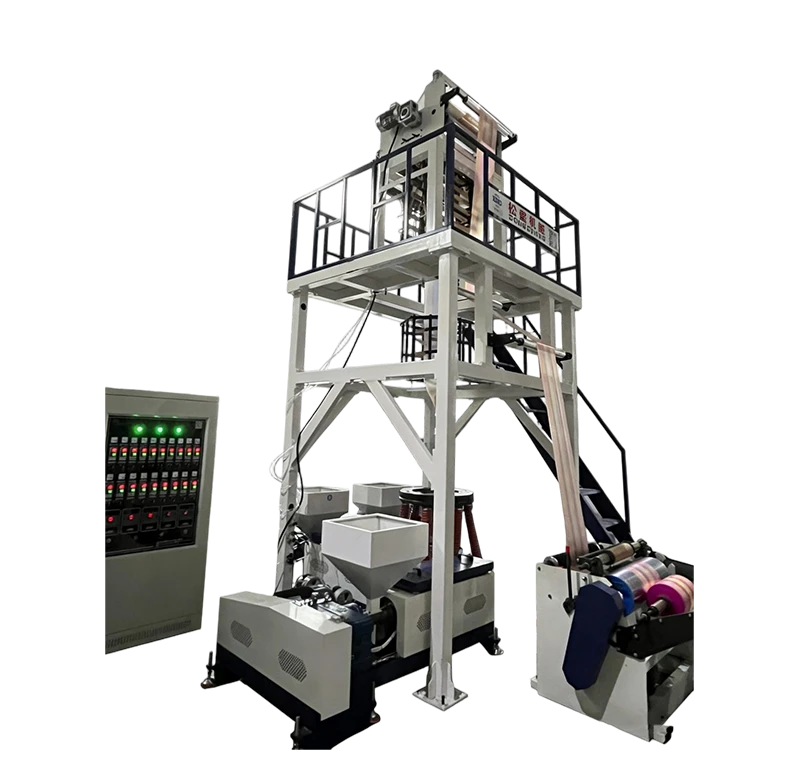

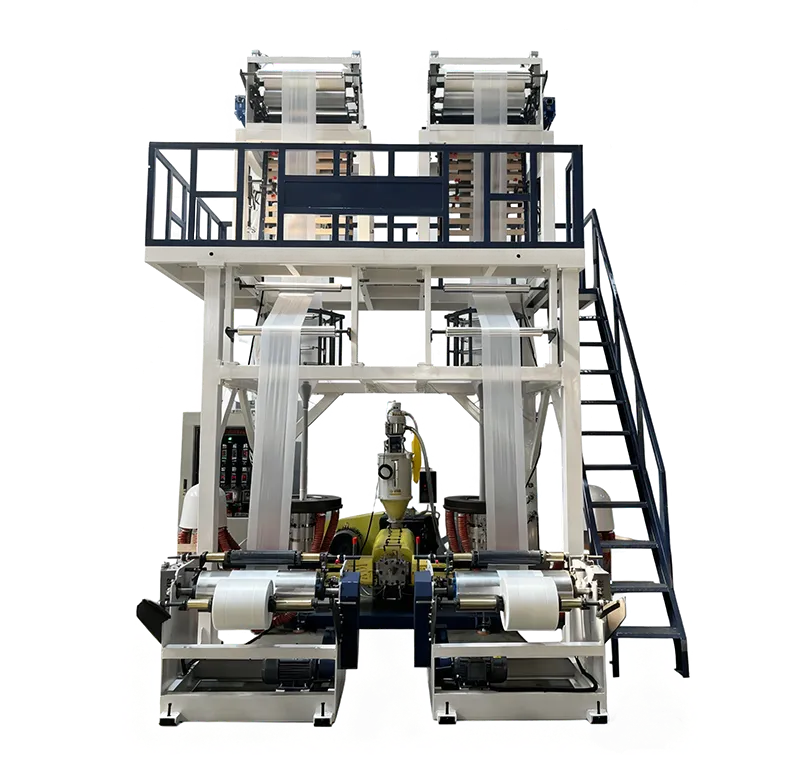

Used for blowing low-density polyethylene (LDPE) and high-density polyethylene (HDPE) plastic films. It can be made into various vest bags, flat bags, and widely used in packaging for food and clothing etc.

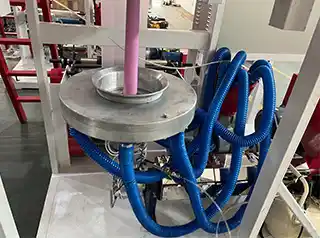

The barrel and screw of the extruder are made of 38CRMOAL alloy steel, which has been nitrided and precision processed.

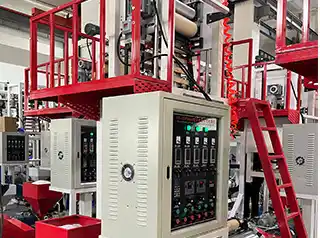

The machine has designed with extruder, die head, traction, and winding are into integrated, occupying a small factory space.