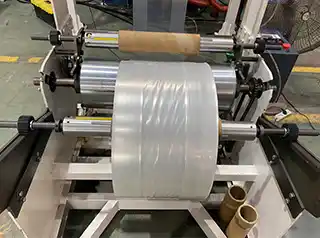

Used for making plastic composite films such as low-density polyethylene (LDPE), high-density polyethylene (HDPE), and linear low-density polyethylene (LLDPE). Widely used in liquid packaging, print-base material, export product packaging, industrial product packaging, etc.

Two layer co extruded composite film can extend the shelf life of liquid packaging.