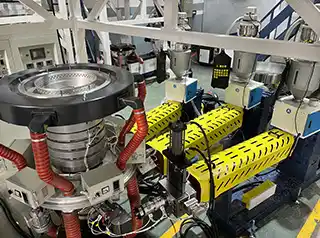

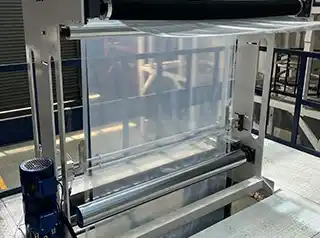

The three-layer plastic co extrusion blown film machine is developed by our factory according to market needs. It can continuously blow various packaging films, that has feature of good barrier property, rainproof, windproof, frost resistant, oxygen resistant and oil resistant.

This film can be widely used in light and heavy packaging, such as various fresh fruits, meat foods, pickled vegetables, fresh milk, liquid drinks, etc.