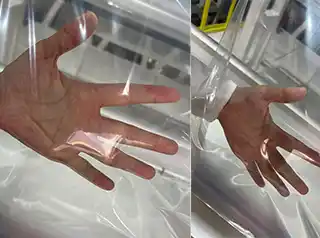

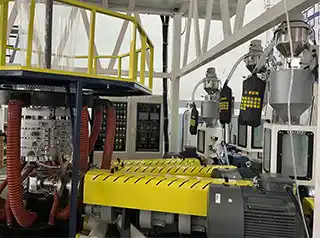

It can be widely used in the production of various high transparency packaging films, such as heat shrink film, heavy-duty film, composite film, express bag film, etc., which greatly help customer to creat considerable economic benefits.

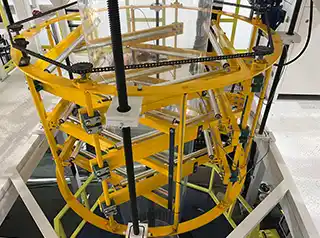

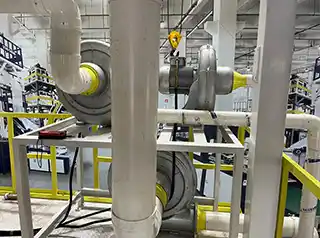

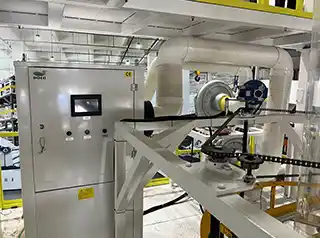

Compared with similar equipment, it has advantages such as a more compact structure, higher output, better product quality, more energy-efficient, and easier operation.