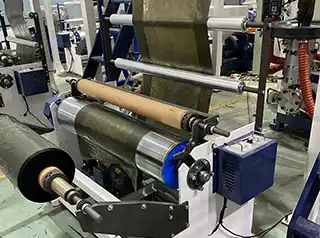

For packaging manufacturers focused on efficiency, versatility, and cost control, blown film machine are more than just another piece of production equipment; they are a key driver of profit growth. Unlike cast film machines, which prioritize surface smoothness, blown film extrusion equipment excels at balancing mechanical performance, material adaptability, and customization potential. These three factors are precisely what modern packaging production demands. Based on 2025 industry standards and real-world case studies, SongSheng's blown film solutions demonstrate that this technology is perfectly suited for food, medical, industrial, and biodegradable packaging applications.

Mechanical Advantages for Enhanced Packaging Durability

The true advantage of blown film technology lies in its simultaneous biaxial stretching during the forming process—a characteristic that gives the film a toughness unmatched by cast film processes. Here's how it works: as the molten resin is extruded into a tube and inflated, the film is stretched horizontally as the bubble expands and vertically due to differences in the take-up speed. Comparative testing conducted by a leading food packaging company found that PE film produced using SongSheng's multilayer co-extrusion blown film machine had 35% higher tear strength and 28% higher impact strength than cast film of the same thickness. This is a significant advantage.

This improvement in mechanical performance is crucial for packaging products such as frozen food bags or heavy-duty industrial packaging. For example, one of SongSheng's meat processing clients saw their frozen meat packaging breakage rate drop from 4.2% to 0.8% after switching to our customized blown film machine—a huge success that significantly reduced after-sales losses.

Broad Material Compatibility for Diverse Packaging Needs

Modern packaging demands an increasing number of functional materials, and blown film machines outperform their competitors in terms of material versatility. SongSheng's equipment can handle LDPE, LLDPE, MLLDPE, PA, EVOH, and even biodegradable materials such as PLA/PBAT. This means one machine can produce barrier films, cling films, and eco-friendly bags—without the need for multiple pieces of equipment. Unlike cast film equipment, which struggles with crystalline resins, our biodegradable blown film equipment can incorporate 30% corn starch into the raw materials without compromising film integrity. This groundbreaking technology has received ISO 14855 biodegradation certification. Precise Control and Cost-Effectiveness to Meet Large-Scale Production Needs

The industry standard for 2025 requires film thickness deviation to be controlled within ±2%, but SongSheng's intelligent blown film machines, with their IBC internal cooling system and automatic thickness monitoring function, far exceed this standard. In a 30-day large-scale production test conducted at a beverage company, our equipment controlled thickness accuracy to within ±1.2%, reducing the scrap rate from 5% with traditional equipment to only 1.1%. This translates to significant cost savings in large-scale production.

The cost savings extend beyond this. Cast film production lines require 30% more upfront investment, while SongSheng's blown film machine, with its optimized screw design and heat recovery system, reduces energy consumption by 18%. A medium-sized packaging factory in Guangdong switched to our high-speed model and increased its daily output from 5 tons to 8 tons, reducing unit production costs by 12%. This resulted in a win-win situation for both production efficiency and profitability.

Providing Customized Solutions for Diverse Application Scenarios

As packaging needs become increasingly diverse, equipment flexibility is crucial – and SongSheng's customized services are our strength. No matter how unique your application scenario, we can tailor the equipment to your needs.[You can contact us through SongSheng's contact page.]