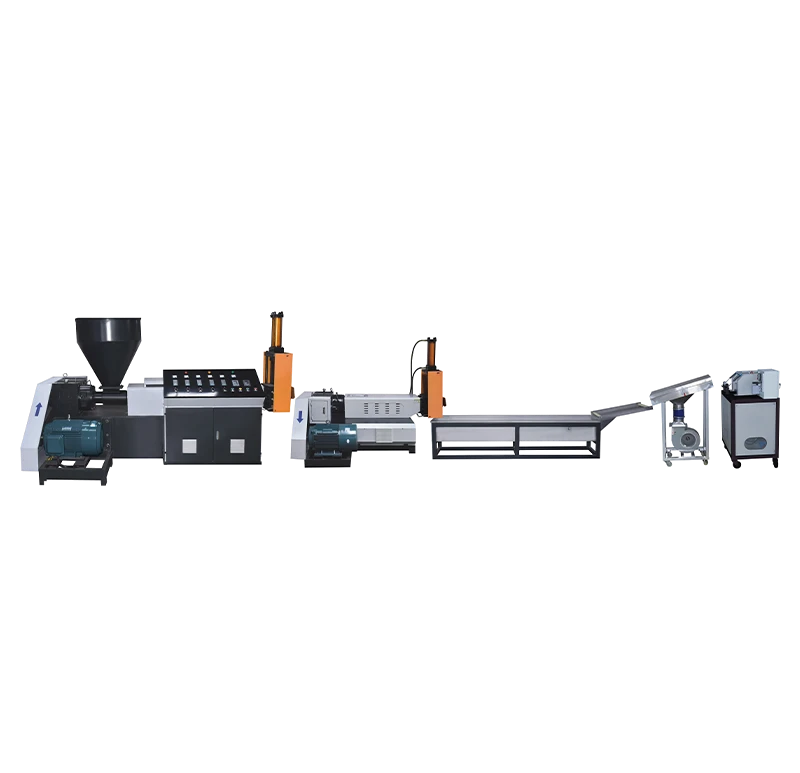

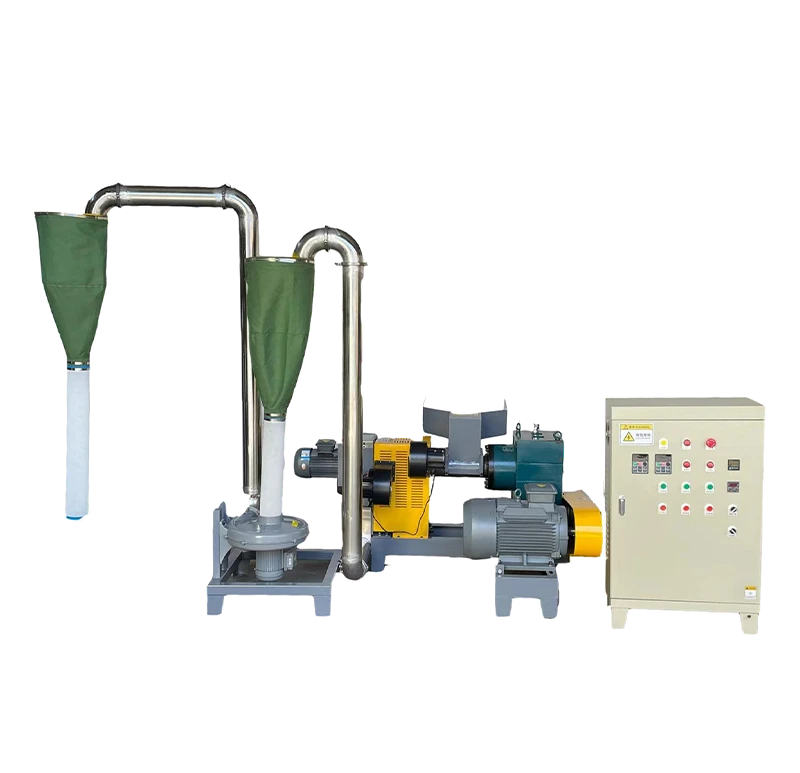

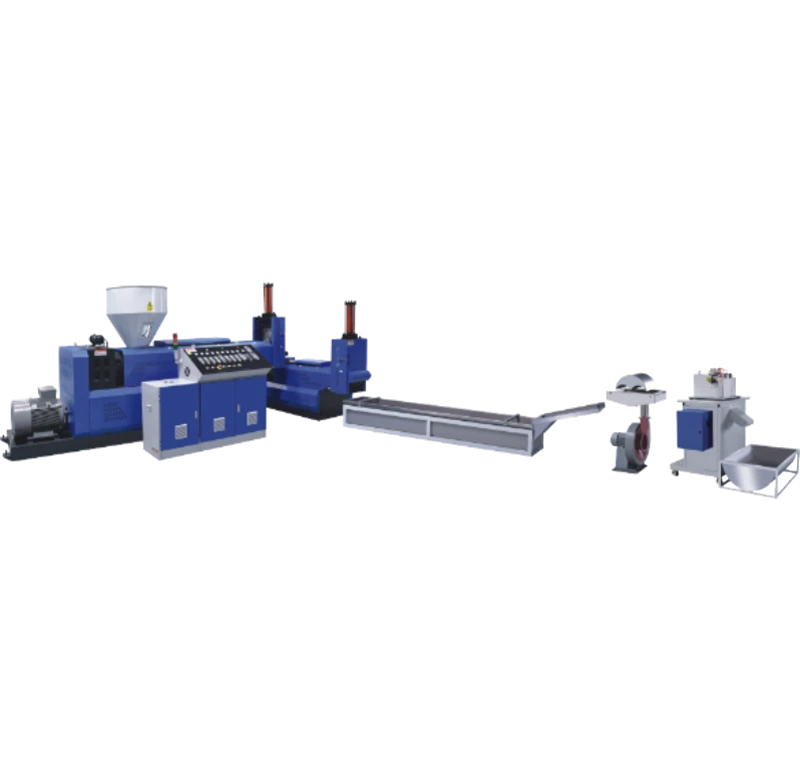

The granulator recycling machine is a very important industrial equipment, its basic function is to press waste materials into solid particles, and it is widely used in multiple industries such as chemical, pharmaceutical, and food processing. Recycling of plastic waste generated in daily life and production can improve production efficiency and economic benefits.

Basic Parameter

|

Model |

SJ-120 |

|

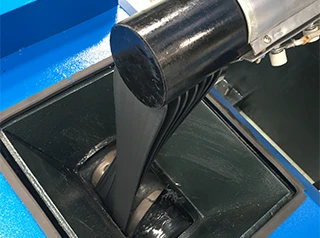

Raw material |

PE/PP |

|

Output |

150-200KG/H |

|

Screw of First Stage |

Φ120mm × 2400mm (38CR with vent) |

|

Screw of Second Stage |

Φ120mm× 1200mm (38CR with vent) |

|

Gear box |

200×1,173×1 |

|

Motor |

37KW×1, 15KW ×1 |

|

Inverter |

37KW×1, 15KW ×1 |

|

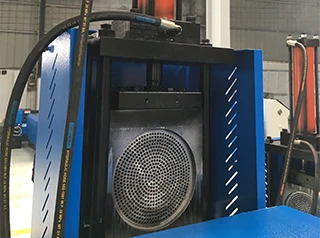

screen changer |

Hydraulic type |

|

Cooling system |

stainless steel tank2500mm*400mm*350mm |

|

Cutter system |

2.2kW |

|

Machine Voltage |

380V 50HZ (can be customizable) |

|

Machine weight |

2.5T |

|

Machine Dimension |

L4.5*W2.5*H2.0m |